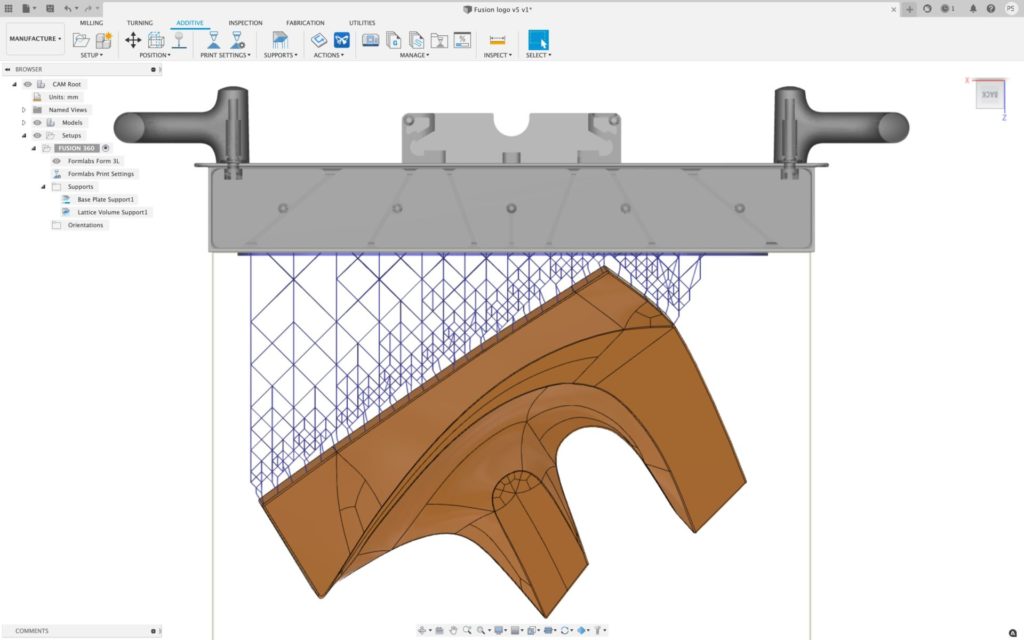

The raw data is imported into Fusion 360 and cleaned up in the Mesh Workspace, and Fusion’s powerful parametric modelling tools are used to reverse engineer a precise replacement part. Mark’s proposed workflow starts by capturing a worn part with a laser scanner. This could circumvent the days or weeks long lead times usually needed to deliver parts if something breaks in the field. The UK’s largest water company United Utilities reached out to evaluate the use of optical scanning and 3D printing to manufacture small replacement parts on demand. With a fleet of over 65 FDM, SLA, and metal 3D printers acquired from Formlabs largerst partner in the UK, Additive-X, Mark consults with companies to conduct feasibility studies on new digital technologies. Mark Chester is a product development specialist at 3D printing hub PrintCity within Manchester Metropolitan University.

0 kommentar(er)

0 kommentar(er)